friction tests|friction coefficient tester : service The overall goal of this guide is to provide a reporting format that will enable computer databases to be readily established. These databases can be searched for material . WEB3 de jul. de 2022 · Quem é ativo no TikTok, provavelmente, já ouviu falar em Lelê Burnier. A carioca é influenciadora de moda e ficou conhecida no aplicativo pelos seus vídeos no formato 'get ready with me .

{plog:ftitle_list}

Resultado da 19 de fev. de 2024 · Ignition Casino Review Overall. Ignition Casino was established in 2016 and is now owned by Beaufort Media B.V. Envisioned as a US-friendly gambling site, Ignition has a lot to offer to its players, from game selection to a strong bonus and nice promotions.. Until recently, Ignition .

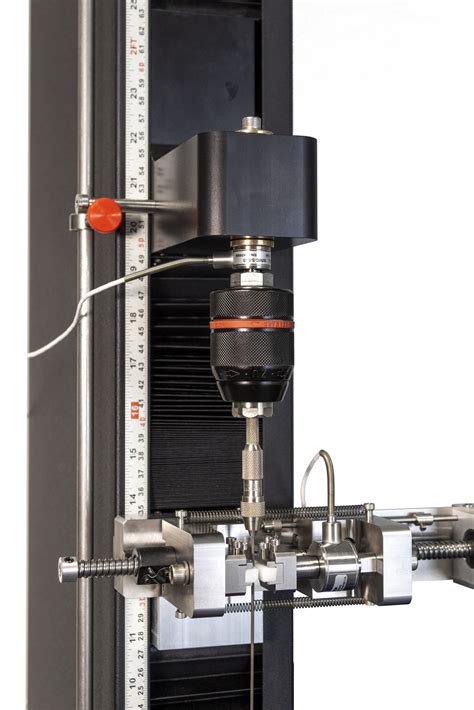

What is friction testing? Friction testing is a process used to measure the resistance to motion of one object moving relative to another. It involves determining the Coefficient of Friction (CoF), which quantifies the frictional .Learn about friction testing and the material testing solutions we provide to cover your needs within friction testing.The coefficient of friction (COF) tester is designed to measure the static and kinetic coefficients of friction of plastic film, plastics textile, sheeting, coated metals, leather printed cartons, packaging substrates, paper, and other surfaces.

What is a friction test? In tribology, measurement of friction consists of the evaluation of forces that occur and oppose a relative motion in a tribological contact. According to ASTM standard G 40, the friction force is “the resisting .

The overall goal of this guide is to provide a reporting format that will enable computer databases to be readily established. These databases can be searched for material .This section explains the essential friction, wear, and abrasion resistance tests for moving parts; the tribological test; and the observation, analysis, and measurement of test specimens.Friction testing allows quality control professionals to determine the coefficients of starting and sliding friction of materials such as plastic films, sheeting, household items, conveyor belts, and more.

Measuring coefficient of friction is done using a Coefficient of Friction Tester or Friction Tester / Slip Tester for short. The coefficient of friction measurement device will have a sled of a known / controlled size and weight and either a .ASTM D1894 Coefficient of Friction Testing. Coefficient of friction testing measures the ease with which two surfaces in contact are able to slide past one another where there are two different . Choosing a friction testing platform that can be quickly adapted for different test conditions and environments has the benefits of providing both flexibility and cost savings to the users. Because friction is directly related to .Coefficient of friction (COF) is the maximum value of the frictional force divided by the normal force. Coefficient of friction (COF) testing is used for a variety of materials from lubricants, to films to household items (ceramic tiles) to .

This article describes the techniques for measuring friction, namely, inclined-plane method; friction test methods using weights and pulleys; friction tests of shafts and capstans; other types of friction tests, including standards; microscale friction tests; and friction testing under well-lubricated conditions.

friction testing machine

line indicating the glass friction angle. Plot the peak friction angles (maximum value for a given test) and the residual friction angles (value at the end of shearing) at the current void ratios. • A summary table of the initial, peak, and final void ratio, the peak and residual friction angle, and the maximum rate of dilation for each test.The coefficient of friction (COF) test measures static and kinetic friction. FUTEK LSB206 load cell can accurately measure friction forces maintaining a nonlinearity of ±0.1%. When performing coefficient of friction testing to ASTM D1894 standard it is essential to use a high precision force sensor and high sampling rate instrument.

zwick roell hardness tester price

Simulative tests to characterize friction include test to reflect bending under tension, pulling through draw beads, and movement over flat surfaces. Depending on the test, it may be possible to evaluate the effect of tooling material, temperature, radii, and speed in order to better simulate production conditions. Traditional friction testing challenges. Traditionally, friction testing has been relegated to occasional spot checking in labs using conventional incline methods. This required destructive testing in which a portion of metal was cut from a sample, mounted on a flat plane of a second metal, with careful measurement of the inclination angle .Testing and measurement of friction, wear, and material mechanical properties. Tribometers and Mechanical Testers. Research into materials and how materials can be changed to influence strength, integrity, or durability is an integral part of product design and improvement across nearly every industry. Bruker's mechanical testers and .

Paper friction tests are essential in many industries, especially paper and packaging. You might also have heard the wear tests, similar to the friction tests. But as the word wear, it means wearing, grinding, or rubbing away by friction. Wear test is a test to observe the destruction of objects.Understanding coefficient of friction testing. Used to find out what happens when two items rub against each other, coefficient of friction testing can be carried on a wide range of materials. It is a straightforward and standardized method of determining the moving and starting resistance of one surface that is being dragged across another and . Friction is defined as the resistance offered by the surfaces that are in contact when they move past each other. Know examples, causes, types, effects, numericals . Get help from the experts at Testbook to prepare for the exams with selective study material, mock tests, and valuable insights all designed to help you score better marks in the .

friction testing equipment

An accurate friction testing system must enable the peak force to be captured as the sled just starts to move - the static ('initial') friction, also known as the ‘stiction’ effect - and also detect 'kinetic' frictional properties, where the surface judders under dynamic ‘stick-slip’ during the moving phase of the test. Coefficient of . This chapter presents a review of accelerated friction and wear-test screening methods. It presents the design methodology and typical test geometries for friction and wear tests. First, the chapter discusses the design methodology of a friction and wear test consisting of four basic elements: simulation; acceleration; specimen preparation; and .

For high precision friction measurement, a dedicated friction testing machine, designed to perform accurate and high quality analysis of your test results, is required. FT1 Friction Tester The FT1 friction tester is a perfect choice to easily measure static and kinetic coefficients of .Coefficient of friction testing measures the ease with which two surfaces in contact are able to slide past one another where there are two different values associated with the coefficient of friction – static and kinetic. Static friction applies to the force necessary to initialize motion between the two surfaces and kinetic friction is the .

Friction tests are instrumental in identifying the optimal tire compounds and tread patterns that offer superior performance across diverse road surfaces and weather conditions. These tests aid in the development of advanced .

Friction Testing. A Brief History. For decades, the road maintenance industry has conducted laboratory tests on pavement friction solutions. In 1992, the Strategic Highway Research Program (SHRP) .Additional information on friction testing methods may be found in companion articles on brakes, engines, and other applied subjects. Indirect friction measurements. Friction, both static and kinetic, can be measured indirectly by monitoring such parameters as the current drawn by a motor that moves one of the sliding components against one .

Coefficient friction testing is important for many industries, such as packaging, plastics industry, and other related industries, where sliding friction can affect the quality of the product. Testing the CoF of plastic films and other packaging materials is an essential part of ensuring that it meets the required standards. A CoF test will . Advancements in Friction Testing. With advancements in technology, modern Coefficient of Friction Testers offer enhanced capabilities. Some models feature computerized control and data acquisition systems, allowing for automated testing and real-time data analysis. These systems offer comprehensive graphical representations and statistical .

In the case of a very unsteady friction signal, friction force measurements must be interpreted with care; it is problematic to deduce a unique coefficient of friction from such tests. Use of a bandwidth that is too low in the electronic recording system can mask the dynamic properties of friction forces resulting, for example, from stick/slip .

friction tester machine

friction tests from low drop heights. Upon analysis of a video clip of a motorcycle incident that occurred at highway speeds under real-world conditions, we found that the motorcycle experienced a higher deceleration during the initial contact with the pavement than it .NANOVEA Laboratory provides a wide range of solutions for friction testing, wear testing and tribology services from ASTM and ISO to custom solutions. Products. Profilometers. PS50 (Advanced Compact) JR25 (Portable Compact) ST400 (Modular Standard) AFMPRO (Atomic Force) ST500 (Modular Large Area)

Floor slip resistance testing is the science of measuring the coefficient of friction (or resistance to slip accidents) of flooring surfaces, either in a laboratory (before or after installation) or on floors in situ. Slip resistance testing (or floor friction testing) is usually desired by the building's owner or manager when there has been a report of a slip and fall accident, when there has .The article discusses the tests and equipment available for friction testing. It explains the procedural considerations that should be addressed to ensure that valid data are derived from a friction test. The article presents definitions of terms commonly used in tribology such as static friction, kinetic coefficient of friction, stick-slip .

When you are walking, static friction pushes in the direction of you are trying to move (see Figure 2 below). The foot pushes on the ground, and without friction the foot would slide backwards (like walking on ice). Static friction pushes in the direction that prevents your foot from sliding, which results in forward motion.

The Noble’s test (Noble's Compression test) is a provocative test of the iliotibial band, developed by Clive Noble. . Repetitive strain, improper footwear, lower extremity mal-alignments and muscle imbalance cause increased friction. Iliotibial band (ITB) friction syndrome is an overuse injury common in runners, cyclists, weightlifters .

zwick roell shore hardness tester

zwick universal hardness tester

Resultado da Corno filmando a esposa chupando o pauzão do comedor 🤤 Nosso Vip: 👉 @Casaisxxxbot 👇 Canal Grátis só para Cornos: @casaisxxx 👇 Grupo Grátis .

friction tests|friction coefficient tester